A metal bending machine is defined as a tool that plays a role in bending metals. The device will be useful in enabling a bend into a work piece. A bow is manufactured by using a machine in a rotating or even during a linear move. It’s a process where the metal can be deformed in the process of applying a force to the subject. The process will make the metal to bend at an angle to form an anticipated shape.

The most common shapes that a metal bending machine will deliver include the V and the U shapes. The metal bending machine is a small investment that will provide adequate production. The metal bending machine is sometimes known as a brake. It will be significant right angles and curved folds. You can also use the tool to shape the metals to get the required shape and size.

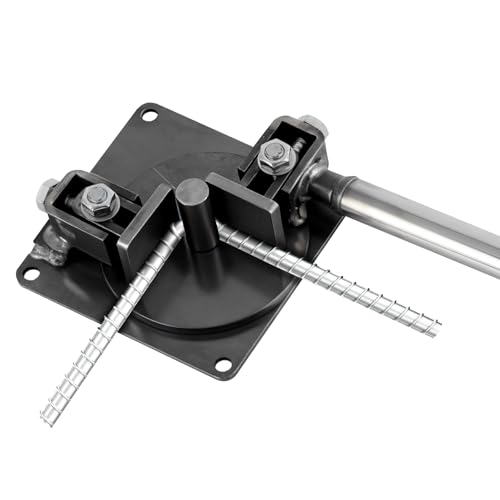

A metal bending machine has a clamping bar that will hold the metal to be worked on in a firm position. You will place the metal to be shaped between a punch and dies tools. What happens is that the upper part often referred to as the punch exerts pressure while the dies as a base tool, allow the room where the metal will take shape.

The front plate of the metal bending tool has hinges that can be lifted like a gate. This fantastic tool will follow the plate as it bends. The clamping bar will play a role in making straight bends. The metal bending machines are available in different sizes, and the choice will entirely depend on your requirements.

To summarize, the metal bending machines are hand-operated, and the body is made of heavy-duty cast iron. They will have handles, a bending bar, and also a bending plate! All these are the specific features that you will expect this machine to possess.