The HIPOGT Pulse Argon Arc Spot Welder is a masterful tool, a silent sculptor in the hands of a jeweler, and a true revolution in the world of delicate metalwork. This automatic spot welder, operating at 110V, is not merely a machine; it is a precision instrument, designed to seamlessly fuse metals with the deft touch of an artist. It harnesses the power of a focused pulse, creating a pinpoint weld that is as strong as it is beautiful. Furthermore, its versatility is a testament to its engineering, as it handles a wide range of tasks from jewelry welding to intricate repairs. Consequently, it has become an indispensable companion for artisans and hobbyists alike, offering a level of control and accuracy that was previously unimaginable. In essence, the HIPOGT Pulse Argon Arc Spot Welder transforms the often-brute force of welding into a dance of light and heat, allowing for the most intricate and subtle of creations.

Beyond its technical prowess, this remarkable device is a beacon of efficiency and user-friendliness, embodying the perfect marriage of power and control. It functions as a bridge between the raw materials and the finished masterpiece, ensuring that every connection is flawless and enduring. Moreover, with an adjustable amperage range of 50-600A and a power output of 100W, it provides the user with an extensive palette of options, making it suitable for a diverse array of metals and projects. For instance, when mending a delicate chain or joining a chunky clasp, the user can fine-tune the settings to achieve the ideal weld. In addition, its automatic functionality removes the guesswork from the process, thus allowing the craftsman to focus on the artistry rather than the mechanics. Therefore, the HIPOGT Pulse Argon Arc Spot Welder is more than a tool; it is a collaborator, working alongside the jeweler to bring their vision to life with unparalleled ease and precision.

Ultimately, the HIPOGT Pulse Argon Arc Spot Welder is a testament to the fact that great power can be controlled with exquisite delicacy, much like a whispered secret holding immense weight. This welder is a silent partner in the creation process, patiently awaiting the user’s command to deliver a burst of focused energy that unites materials forever. Instead of leaving behind unsightly marks or blemishes, it forges a bond so clean and minimal that it appears as if the pieces were always one. Moreover, it is a tool that elevates the craft itself, providing the confidence and capability to tackle even the most daunting of repairs or designs. In conclusion, the HIPOGT Pulse Argon Arc Spot Welder stands as a symbol of innovation and precision, turning the arduous task of welding into a simple and elegant act of creation, and proving that the finest work is often done with the quietest of tools.

FEATURES:

– Automatic spot welding for jewelry

– Pulse argon arc welding

– Adjustable current: 50-600A

– 110 Volt input power

– 100 watt power consumption

– Compact desktop design

– Foot pedal included

– Suitable for jewelry repair

– Includes all necessary accessories

– Ideal for intricate metal work

The HIPOGT Automatic Spot Welder is a compact desktop tool for jewelry repair and intricate metal work. It uses pulse argon arc welding with an adjustable current of 50-600A. Operating on 110 Volt with 100 watt power consumption, it is controlled by a foot pedal and includes all necessary accessories, making it ideal for jewelry welding.

– Works great!

– Looks easy to do

– Worked correctly for 8 months

– Manufacturer sent new plate

– Problem was solved

– Good for the price

– Decent for the price

– Helps with permanent jewelry

– Youtube helps with instructions

– Vendor was excited to buy

– Lacks instructions

– Not everything comes in the package

– The machine arrived broken

– Burned through gold pieces

– Technical issues with tungsten tip

The HIPOGT Automatic Spot Welder is a 110V, 100 watt machine with a 50-600A range, suitable for jewelry welding and repair. Users found it to work great for permanent jewelry and easy to use, with some noting that YouTube tutorials were helpful for instructions since the included instructions were lacking. While some experienced issues such as receiving a broken machine or burning through gold pieces, others had positive experiences, with one user noting the manufacturer promptly sent a new plate to resolve a technical issue after 8 months of use. The welder is generally considered a good value for the price, though some buyers reported that not all parts were included in the package and there were issues with the tungsten tip. Read more…

Automatic Jewelry Welder’s Smooth Wire Feeding

This image shows the benefits of the HIPOGT Automatic Jewelry Welder. The top part shows how the welder uses an inner wire feeder. This feature helps ensure smooth wire feeding. The bottom part compares the weld quality of this product versus others. The “OURS” side shows a continuous, smooth weld. The “OTHERS” side shows a discontinuous, rough weld. This highlights the product’s superior performance for delicate jewelry work.

HIPOGT Jewelry Repair Welder Specifications

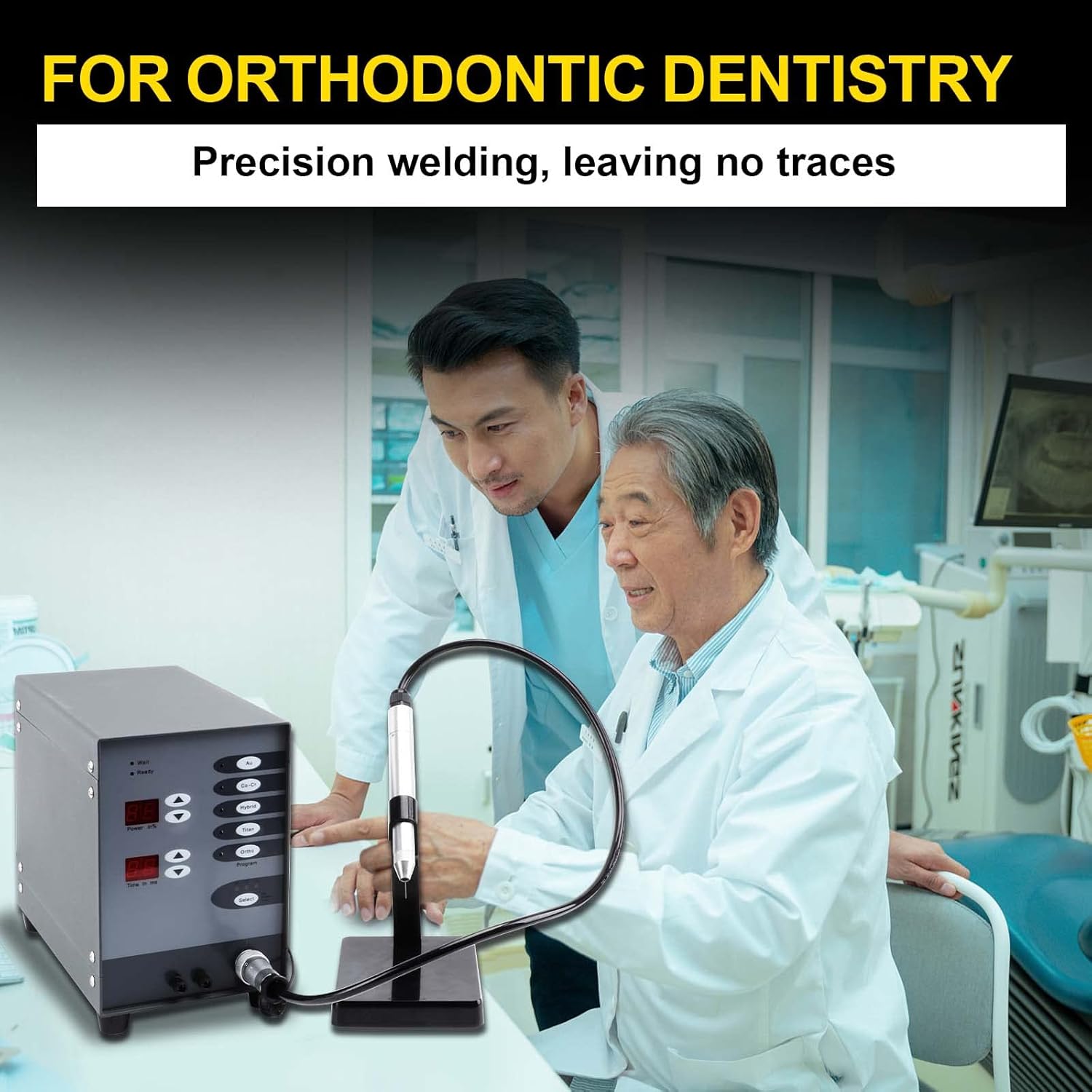

The image shows the HIPOGT 110 Volt Jewelry Repair Welder. It highlights the product’s specifications and features. The machine has a digital display for power and time settings. It has buttons for different materials like Au, Co-Cr, Hybrid, and Titan. The product dimensions are 9.2 in x 6.1 in x 11 in. The input power is 110W. The welding current is 50A-600A. The image also shows examples of its use, including jewelry repair and orthodontic welding.

HIPOGT Multi-Process MIG Welder for Jewelry

This image shows a HIPOGT multi-process MIG welder. It is designed for jewelry repair and welding. The main unit has a digital display. It shows power settings and time in milliseconds. A small welding pen is held in a stand. The pen is connected to the main unit by a cable. The welder is shown being used on a piece of jewelry.

Jewelry Spot Welder Control Panel

This is a control panel for a jewelry spot welder. The panel features a digital control system. It has two digital displays for adjusting welding power and time. There are also buttons for different welding modes. These modes are for materials like Gold, Cobalt Chromium Alloy, and Pure Titanium. An orthodontic dentistry mode is also available. The panel has interfaces for the welding handle and a negative circuit.

Professional Dental and Jewelry Welder Kit

This image shows a complete HIPOGT Pulse Argon Arc Spot Welder kit. It is designed for welding various metals, including gold (Au), cobalt-chrome (Co-Cr), titanium (Titan), and for orthodontic (Ortho) work. The main unit is a gray box with digital displays for power and time settings. It has buttons to select different welding programs. The kit also includes a welding pen, a foot pedal, a power cord, and various accessories. These accessories are for precise welding tasks in dental labs or jewelry making. It appears to be a professional-grade tool.

HIPOGT Jewelry Repair Welder’s Technology

This image shows the HIPOGT 110 Volt Jewelry Repair Welder’s capabilities. It highlights the use of IGBT Inverter Technology. This technology provides a stable arc for consistent welding. The image also shows the types of materials the welder can be used on. These materials include gold, stainless steel, and iron. It is a versatile tool for jewelry repair.